The intelligent warehouse management system organically combines database technology, communication technology, network technology, data collection technology, and automatic identification technology with warehousing functions to achieve accurate, efficient, and real-time item information storage and management effects, so as to better satisfy The in-depth integration of the industrial Internet platform requires the construction of massive logistics business data collection, aggregation, modeling, analysis, and services, promotes the platformization of warehousing management, improves the level of information integration, and can also ensure the sound development of logistics enterprises.

Contents

1. The background of intelligent warehouse management

Due to the lack of information system support, the overall level of intelligence is low, most warehouse management is still dominated by manual processing, a large number of repetitive operations and costs are repeatedly invested, high operating costs and low efficiency; inventory and maintenance information is lagging, and intelligent analysis cannot be achieved, Management, and tracking, it is difficult to carry out batch management and product traceability, and cannot meet the requirements of the overall development plan, so it is necessary to build a warehouse management system to solve the current practical problems and improve the level of information integration.

Demand analysis of warehouse management

Follow the informatization construction ideas of “unified platform, unified data, unified network, and unified standard” to build a unified intelligent warehouse management system. Through the construction of an intelligent warehouse management system, it completely replaces the original manual management method, avoids various errors caused by managerial negligence and management quality problems, and completes warehouse management and centralized scheduling control in a timely, accurate and efficient manner. details as follows:

(1) Satisfy the automation of warehousing operations: by introducing new technologies and combining the equipment in the warehouse to improve operation efficiency, reduce operation error rate, fully grasp the dynamic information of personnel, refine facility management, and further enhance the automation and coordination of the internal operation process of the enterprise warehousing And efficient.

(2) Promote the construction of intelligent maintenance, integrate advanced RFID and other information collection technologies, integrate the automated centralized detection line system for centralized detection, the environmental temperature and humidity in the alcoholization warehouse, and the data collection management function of the main operation nodes, and finally realize the entire warehouse. Process monitoring and recording.

(3) Achieve lean management: modern warehouses that apply bar code and automatic identification technology manage the warehouse process and space, realize batch management, fast storage, and dynamic inventory, and quickly help the logistics management personnel of each tobacco factory to check the inventory Material storage, storage, movement, and other operations are fully controlled and managed, warehouse storage space is effectively used, warehouse storage capacity is improved, and the use of materials is realized first-in-first-out, which ultimately improves the utilization rate of enterprise warehouse storage space and the enterprise The quality and efficiency of material management reduce enterprise inventory costs.

(4) Realize information decision analysis: various records, data, standards, and systems that occur in each warehouse management business achieve in-depth mining, scientific analysis, and rapid feedback, and form the movement of the entire material in and out of the warehouse and in the warehouse process. Controllable management, providing data support for the warehouse management system to realize in-depth mining of inbound and outbound and inventory data.

Refined warehousing management

Intelligent warehouse management: use the Internet of Things, automation, and information technology to build intelligent digital warehouse management, realize the scientific layout of the warehouse, the scientific scheduling of the process, and realize the outgoing, warehousing, and ongoing operations of the raw material warehouse Fine management of the process, improve the level of storage management, improve the efficiency of storage management, reduce storage costs, reduce error rates, optimize the operation process of tobacco leaves, shorten the handling time of tobacco leaves, thereby reducing enterprise production costs and reflecting the economic benefits of storage management.

Accurate environmental management: using sensors and other Internet of Things technology, through the entry and monitoring of temperature and humidity environment, core-spun temperature and moisture, and insect situation information, to achieve a comprehensive perception of environmental data, and through linkage with the environmental regulation system in the library, To form an intelligent environmental monitoring and control system.

Accurate maintenance management: Through intelligent analysis of environmental data, intelligent scheduling of maintenance operations, accurate management of stacking positions in the warehouse, and random inspection management throughout the life cycle, accurate maintenance of raw materials is realized, so that the state and quality of tobacco leaves can be controlled, and the tobacco leaves are improved. The maintenance level of the warehouse.

Sophisticated data services: Provide a basis for decision-making through the collection and processing of various data in the warehouse management; improve the maintenance level of the tobacco warehouse through the processing and analysis of the environment, warehouse operations and maintenance data; use the entire process data Traceability provides data support for the “forward tracing and reverse tracing” of tobacco leaf management; through data sharing with the upstream and downstream links of the supply chain, it provides data support for production formulas.

2. Planning of Intelligent Warehouse Management System

2.1 Smart warehousing basic data management

The various records, data, standards, and systems that occur in the warehouse management business, including the following: location data, barcode data, material data, equipment number, maintenance staff management, warehouse data, group management, system identification, etc., combined with batches Manage information, create and manage electronic files, and provide data support for realizing deep mining of conservation environment data.

The warehouse management system will be integrated with the intelligent park system, centralized inspection line system, warehouse monitoring system, etc., to complete the integration, integration, and improvement of the resources in the warehouse, and realize the whole process of receiving, warehousing, storage, maintenance, and delivery. Informatization centralized management and control, creating a closed-loop business of raw material warehousing and logistics, initially realizing the informatization of the warehouse operation process, the digitization of warehouse management, and the diversification of statistical analysis, providing comprehensive, timely, and accurate data information and strict, standardized, Efficient management and control methods meet the needs of standardized, standardized, scientific and integrated raw material alcoholization warehouse management.

3 The overall system architecture design

3.1 Hardware support

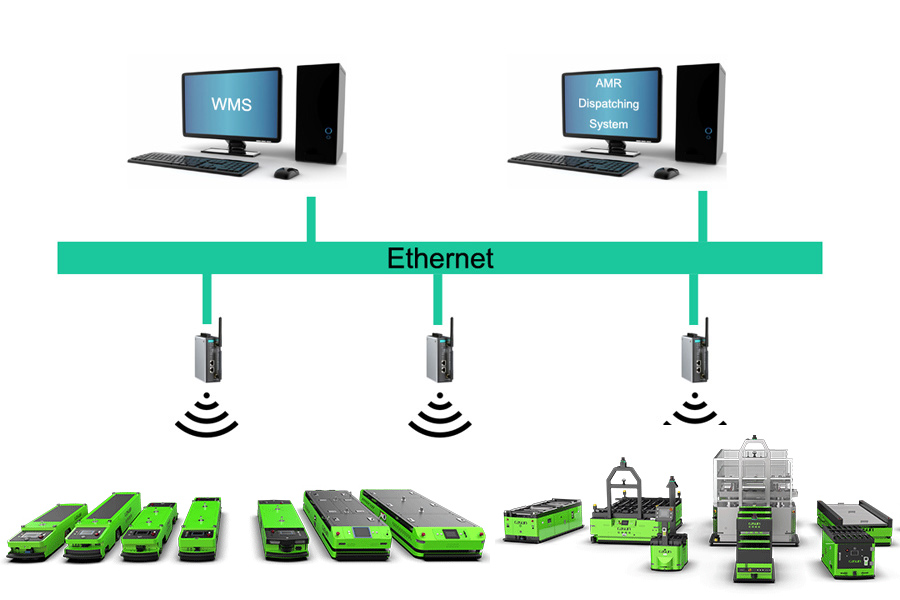

In the warehouse area, the enterprise LAN is used, equipped with a certain number of computers and servers. In order to facilitate the operation of handheld RF, the automatic identification of vehicle terminals, and RFID access doors, wireless APs need to be used in the warehouse to meet the needs of data transmission and users. In addition, corresponding auxiliary equipment such as printers needs to be added to realize functions such as printing of reports, bar codes, and storage positions.

3.2 Software support

Adopt B/S structure and component development technology based on J2EE or .NET multi-layer architecture to design and develop the system architecture, and install the WEB browser to access the TCP/IPTV end of the Internet in the enterprise. Users only need to use a Web browser to process the operations of various functional modules in the system. The advantage of the B/S model is that it can reduce the workload and cost of system maintenance and upgrades, and it also simplifies the client and facilitates operation.

Develop in accordance with unified data standards, including metadata standards, master data standards, information classification, and coding standards, etc., to ensure the standardization and consistency of information system data, and to meet the requirements for full data sharing and application. The intelligent warehousing system uses the Oracle 12C database as the data layer of the system. Oracle 12C database can improve the access efficiency of data files and help different types of data queries. It can effectively solve the detection of system database quality inspection and resolve conflicts. In the development and design of the system, the database is connected through RedHat Linux 7.5, and SQL statements are executed to complete data checking, adding, deleting, and modifying. In addition, .NET, as one of the widely used object-oriented programming languages, has the characteristics of cross-platform, distributed, interpretability, portability, etc., making the implementation of the system safer and more reliable.

3.3 System architecture design

The overall structure of the system can be divided into three levels: decision-making layer/functional application layer, an execution interface layer, and data support layer. The system interacts with users through the decision-making layer/functional application layer and accesses the background database through the execution interface layer to realize the connection, query, call, and temporary storage of the underlying data. The data is maintained by the administrator through the data support layer to ensure functions Data sharing and calling when the module is running.

4 The system module

The construction is mainly to build an intelligent warehousing system for raw materials, through the use of RFID, information integration, and other technologies, based on the circulation and information communication of raw materials, provide complete information services throughout the life cycle of raw materials, and realize an information platform shared by all parties in the business. . The construction function includes main functional modules such as warehouse/warehousing management, quality inspection management, maintenance management, RFID application, mobile operation management, basic information management, etc., and realizes integration with logistics systems, supply chain systems, smart parks, temperature, and humidity systems, etc. And docking.

4.1 Basic Information Management

Basic information management is the most basic records, data, standards, and systems in the warehouse management business. It mainly includes location data, barcode data, material data, equipment number, leaf management, warehouse data, group management, system identification, etc.

4.2 Inbound/Outbound Management

Operators receive tasks from the warehouse management system for processing and feedback the processing results to the warehouse management system. Pre-receiving/outgoing goods in the warehouse area, and forming an in/out notice, form a receipt/out order based on the incoming/outgoing notice, and confirm the formation of an on/off-shelf order, mainly including: in/out Management of outbound notice, receipt, and on/off orders.

4.3 Quality Inspection Management

Quality inspection management means that operators complete quality inspection actions on corresponding areas through mobile terminals. The user can perform quality inspection operations on the materials stored in the library. The system defaults to listing the locations with the material status as “Pending Inspection” for users to choose (the user can specify all locations in a certain area, a certain location, or a certain category). Materials undergo quality inspection). After the user inspects the materials, the current quality inspected materials can be processed in the status of “Quality Inspection Passed”, “Quality Inspection Unqualified” or “Pending Inspection”.

4.4 Maintenance management

Maintenance management is the regular maintenance and maintenance work performed by warehouse managers on stored commodities. Based on the use of wireless sensor equipment, temperature and humidity detectors, and other technologies to detect the storage environment in real-time, from maintenance method collection, maintenance strategy management, maintenance strategy preparation, maintenance plan adjustment, historical maintenance tasks, maintenance task allocation, historical task management, and maintenance tasks Early warning, maintenance operation tracking, and maintenance operation adjustment dimensions, establish material maintenance goals, data collection, task allocation & early warning, historical data query, maintenance adjustment closed-loop control, through the above management measures to achieve the full life cycle of tobacco in the warehouse Management, it is convenient for us to view historical data and do subsequent storage and maintenance operations.

4.5 RFID application

The design is carried out with a scheme of vehicle-mounted RFID, embedded RFID tags, and RFID detection doors. The storage system is integrated with RFID equipment, and data is processed with the RFID system. Processing links include code printing, warehousing scan code, inspection code scan (centralized inspection area, imported quality inspection), maintenance code scan, and warehouse code scan code. Realize the whole process management of inbound and outbound operations, warehouse management, and other businesses, as well as automatic one-time scanning and identification of inbound and outbound, and automatic identification of stamping positions, realization of functions such as inbound and outbound error prevention, and warehouse movement prevention error alarms, and visualized warehouse monitoring Operation.

4.6 Mobile job management

Mobile job management is mainly processed by introducing job tasks issued by the warehouse management system and feeding back the processing results. Mainly realize the functions of temperature sampling, humidity management, core-spun temperature detection, moisture detection records, fumigation management, quality inspection processing, inventory processing, and maintenance, etc., and use wireless equipment to enter data into the system to realize the various links of the logistics center. Mobile real-time management and monitoring of operations and management.

5 Benefit improvement

The implementation and optimization of the intelligent warehousing system is a long-term system engineering. Now, a simple analysis of the warehousing application effect is carried out in terms of operational benefits, management benefits, and economic benefits.

5.1 The purpose of the degree of automation is to improve the degree of informatization of the enterprise and to standardize the process of the enterprise so that it can be recognized by the information system. Through the information transformation of the enterprise, it is possible to have an overall grasp of the execution of orders, the production capacity of the production line, the production capacity of the equipment, and the material inventory, and carry out comprehensive management and control of all links of production. Through the use of RFID technology and wireless network technology, the stack of raw materials is identified, the cigarette box barcode information in the stack of raw materials is stored, and the RFID read and write function is used to combine the barcode with the RFID electronic tag to realize the stacking of the enterprise. Units carry out factory scanning, and raw material circulation companies carry out industrial production out-of-warehouse scanning in units of pallets. And to improve the existing warehouse management level, improve work efficiency, ensure the accuracy of warehouse management and the timeliness of information update, completely change the past information recording and transmission methods, and truly realize the modernization of warehouse management.

5.2 Management benefits. Eliminates the phenomenon of piles of products in the area to be inspected, and achieves direct receipt of incoming goods, direct storage of goods on shelves, and other operations; in the intelligent warehousing system, you can quickly query the location, quantity, quality, grade, etc. of the materials in the warehouse Information, convenient for warehouse management personnel to leave the warehouse. The reaction speed of each node in the warehouse process is improved, and it also provides support for the visualization and transparent management of the information of each node in the warehouse process.

5.3 Economic benefits. With the support of the intelligent warehousing system, the company’s warehousing process information has achieved transparency, standardization, and simplification. The accuracy of material storage information, the efficiency of leaving the warehouse, and the efficiency of inventory counting have all been greatly improved, further reducing the Probability of homework errors. At the same time, the level of material storage management is improved, the labor cost, purchase cost, and inventory cost of the warehouse are effectively reduced, the business risk of the enterprise is correspondingly reduced, and the economic benefit is increased.