The simple AGC is no longer a simple version of AGV with reduced performance, but has a highly modular and integrated control device; the control system and electrical design are standardized so that the AGC can be assembled and wired by assembly-line production. Greatly reduce product cost; AGC’s modular structure can be easily integrated into the corresponding customized mechanical body or simple frame; it adopts electromagnetic or optical automatic guidance devices, which can drive along the prescribed guidance path and has safety protection And transport vehicles with various transfer functions. At the same time, the AGC system also includes the upper-level control and dispatch management system, which can realize multi-vehicle flexible tasks and route allocation and traffic management between AGC.

Contents

1.Design Ideas and Key Realization Methods of AGC System Software

1.1 Material handling plan of the AGC system

- Line-side equipment or operators confirm the material ready information through data communication or the manual button at the AGC loading point;

- The material ready information will be transmitted to the AGC console, and then the AGC console will dispatch the AGC to pull away from the full cart;

- AGC transports the full material truck to the unloading point. The principle of selecting the unloading point is the nearest and idle; when it arrives, it starts the sound and light alarm prompt operation;

- The unloading point can be configured with an LED display to scroll to display tasks, including AGC number, rack number, urgency, executor and other information; each LED display only displays the location of the corresponding unloading point, which can be unloaded by a forklift; the forklift can be equipped with PDA Scroll to display tasks. The forklift driver uses the wireless button box to select the most convenient and most urgent task according to his position status, referring to the PDA and LED display; once a forklift driver selects a task, the task is displayed on the LED The screen will show that it has been executed by the forklift, and the LED and other forklift PDAs will also show that someone has executed it and can no longer choose. If the docking is done by the line-side mechanism, the corresponding AGC will report the console ready for unloading status, and the console will coordinate the docking action. During the process, the interlock signal protection and confirmation are completed;

- The task of conveying empty racks will be arranged in advance according to the present time such as travel distance;

- If the rack needs to be replaced, the ground can be equipped with an RFID reader to read the rack information and perform task verification. If it is correct, the AGC will give a short warning and leave, otherwise, a new task will be generated to replace the wrong rack. The task will also be displayed on the LED and PDA, and the AGC will continue to alarm until it is correctly placed on the rack. After the material rack is correctly placed, the LED and PDA display task status will be completed.

1.2 Task distribution mode of the AGC system

The task allocation of the AGC upper system adopts the detailed mode:

In the specific work, it can be divided into a task of conveying a full-carriage from the loading point to the unloading point, and another task from the unloading point to the loading point. Each AGC is not fixed to serve a certain line.

This model has many advantages:

- Once the AGC breaks down during the execution of the task, it will have a small impact on the overall production and operation, and the workload that requires manual intervention is small.

- Each AGC is more flexible in arranging tasks, which improves the utilization rate of AGC.

- AGC berths are set in the AGC operating line. When the production capacity does not require too much AGC, the AGC console can automatically dispatch the excess AGC to the berths to wait.

1.3 Material switching mode of the AGC system

- The AGC system console can accept the production arrangement of the host computer (for example, obtained from the workshop MES system), and the console can preset the beat data of different material varieties. Under normal circumstances, material switching can be realized without manual intervention;

- The workshop management system needs to preset the time before the material switch, and send the mode change instruction to the AGC console in advance;

- The management machine of the AGC system can realize flexible scheduling without special manual intervention.

2. The composition of the AGC system

AGC system, mainly composed of the AGC control system, dispatch management system, communication system, AGC, automatic charging system, etc.

2.1 AGC control system and AGC dispatch management system

The console is based on PC architecture and has good price advantages and performance expansion capabilities. Its AGC control system and AGC dispatch management system are the dispatch management center of the AGC system, responsible for the data processing of the data acquisition system, and exchange information with third-party equipment and upper computers. Generate AGC operation tasks, solve collision avoidance problems among multiple AGCs, etc.

Due to the centralized control method, the console will become the core of the AGC system movement. It exchanges large-capacity and high-speed data with the main server to complete the data sharing of AGC motion information. The console has an interface with the host computer production scheduling management (such as MES) system to receive scheduling commands and report the operation of AGC. The console meets the requirements of the industrial field environment and has sufficient computing speed and management capabilities. The console will display the working status of the system on the screen while scheduling the online AGC in real-time, including the number of online AGC, the status of the location (including the location of the landmark where the AGC is located), and the number of completed transfers.

The control system is mainly responsible for traffic management in the operation of AGC. Ensure the minimum distance between AGC and AGC during operation, so as to avoid collisions and rear-end collisions. There is a collision avoidance parameter setting file in the AGC console, which can set different collision avoidance principles for different areas to effectively control various conditions The safety clearance of AGC. The console will manage the AGC entering and exiting the system to ensure the safe operation of the system.

The AGC scheduling management system adopts a centralized scheduling management method, which can issue transportation tasks, AGC working status, operation conditions, etc. according to the production management system, and transmit commands and tasks to the selected AGC through the communication system. The selected AGC is managed according to the console The command of the system completes the delivery of the engine. After the task is completed, the AGC informs the console of the task completion status and returns to the standby position to wait for the next task.

The design of the AGC system should automatically complete the maintenance station cache function, that is, when the function is open if the station is blocked, the system can automatically schedule the subsequent AGC into the cache area, and release the AGC at an appropriate time to restore the system to normal operation, this method can reduce the time of production line stoppage under certain conditions and improve the overall production capacity of the workshop.

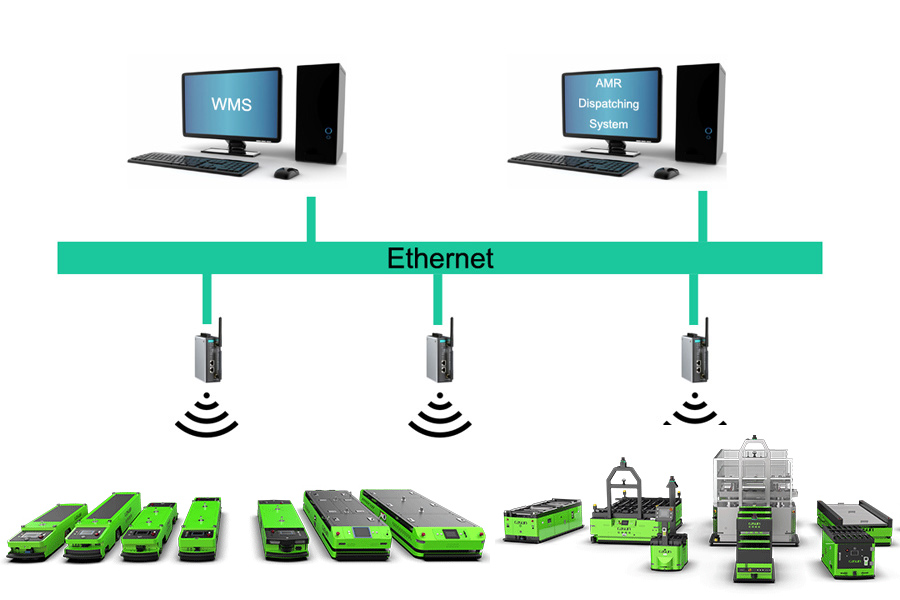

2.2 Wireless communication system

The AGC console and AGC adopt wireless communication, and the console and AGC form a wireless local area network. The console relies on the wireless local area network to issue system control instructions, task scheduling instructions, and collision avoidance scheduling instructions to AGC. The console can also receive communication signals sent by AGC. The AGC relies on the wireless LAN to report the execution of various commands, the current position of the AGC, the current status of the AGC, etc. to the console. If the communication between the AGC console and the AGC is interrupted, it will not cause the AGC to crash or die; when the communication is restored, the AGC can automatically establish communication with the console without shutting down and restarting.

3. Analysis of key points in the design of AGC car body

The AGC design should follow the modular design, and the whole is composed of mechanical and electrical parts. The mechanical part generally includes AGC frame, drive wheel assembly, follower wheel, feeder guide and positioning device, battery compartment, control compartment, etc. The electrical part generally consists of battery modules, AGC controller systems, servo systems, radio stations, sensors, and wiring harnesses.

3.1 Safety control design

As the AGC operating area is divided into unmanned and manned areas, in order to ensure the AGC’s own safety during operation, especially the safety of personnel on-site and the safety of various equipment, AGCS should take multi-level safety measures.

Software protection: including deviating navigation line protection, landmark loss protection, navigation belt defect protection, component failure protection, communication failure protection, light target loss protection, over-tolerance protection, stall protection, etc.

Hardware protection:

- Install an emergency stop switch on the body of the AGC. Press this switch at any time and the AGC will stop running immediately. AGC installs eye-catching signal lights and sound alarm devices to remind the surrounding operators.

- On the AGC car body, non-contact anti-collision and mechanical contact bumpers (optional) are set in the forward direction, and the anti-collision and bumper signals are connected to the AGC safety circuit. Non-safe non-contact collision avoidance can be installed in unmanned areas, and safety non-contact anti-collision and mechanical contact bumpers (optional) must be installed in occupied areas. At the same time, operation prompt functions such as warning lights or buzzers must be designed. Device.

- In the electrical design of AGC, in addition to safety controllers such as safety PLCs, ordinary controllers need to use safety relays to control the drive circuit, which improves the safety level of control. When the emergency stop signal on the AGC body is triggered, a safety reset circuit needs to be designed to manually confirm the reset, so that the AGC can continue to run to increase the safety of the operation.

Once the computer system fails, the offline protection unit, collision avoidance safety unit, emergency switch, etc. will control the AGC to stop or complete basic operations. When a failure occurs, AGC automatically uses sound and light to alarm. At the same time, the AGC monitoring system is notified through the wireless communication system. The AGC monitoring system displays the current status and text prompts on the console. The monitoring personnel can direct the on-site personnel to troubleshoot according to the prompt information. If the AGC fails, you can use the manual operator to control the AGC. When the AGC fails and the power supply or power system fails, there must be a convenient way in the mechanical design to easily push the AGC to the maintenance area.

3.2 Mark design

AGC should design the corresponding nameplate, which includes: model, basic parameter information, safe walking speed, and other parameters. The nameplate should be placed in a conspicuous location, clearly legible and non-erasable (for example, waterproof).

At the same time, warning signs should be designed for components with potential or accidental risks, which should meet the requirements of GB/T 26560-2011. Warning signs related to hazards should be posted on or near the relevant hazardous accessories of the mobile robot. The following or equivalent content should be marked near the battery or battery compartment, such as “Warning: Risk of fire or explosion! Only replace it with the same type of battery.”

For non-safe laser scanners, clear markings should be made to prevent lasers from damaging human eyes.

4. Conclusion

The AGC system introduced in this article, while maintaining the low cost and flexibility of the traditional AGC, also has highly intelligent and automated control and scheduling functions, so that AGC can be configured in a large number of smart factories, and truly realize flexible management.

Due to the composition and design concept of the control framework of the AGC system, following the robot design specifications and standardization, the system becomes relatively simple in the later transformation and maintenance of production logistics, even if major functional changes are made, it will not waste too much Human and financial resources have truly brought into play the simple and flexible characteristics of AGC.