Both WMS and AMR systems are very important components of factory automation logistics. The material information of the warehouse is sent to the AMR system, and the AMR system automatically dispatches the corresponding AMR trolley to the designated outbound station to pick up the goods, and then transport it to the corresponding processing station through the planned route to complete the outbound task. Similarly, finished products, semi-finished products, surplus materials, waste materials, etc. processed in the production workshop are sent to the AMR system via WMS. The AMR system automatically dispatches the corresponding AMR trolleys to the designated stations to pick up the goods, and then transport them to the three-dimensional warehouse via the planned route. The corresponding warehousing station completes the warehousing task. For WMS and AMR systems that operate relatively independently, how to connect these two systems to realize the synchronous transmission of logistics and information flow is of very important significance.

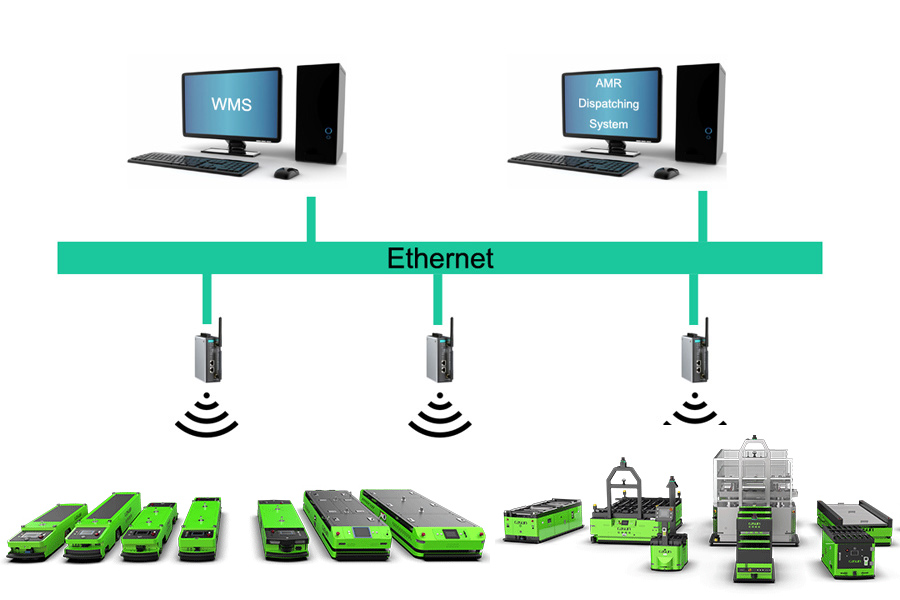

Network structure of AMR dispatching system

In a typical AMR application system, a database server is configured for centralized data storage, and the WMS is sent to the AMR dispatch system installed on the server via the Ethernet as a database or datagram. The AMR dispatch system generates AMR jobs according to the content of the intermediate table in the database or after parsing the messages and dispatches the AMR to transport the trolley to perform the corresponding handling tasks. The AMR needs to interact with the equipment control system at the place of picking up or unloading to complete the picking and unloading. operating. The network structure of WMS scheduling AMR is as follows:

WMS and AMR dispatching system interface mode

WMS is installed in the WMS server. When the database intermediate table interface mode is adopted, WMS writes the warehouse operation into the intermediate table, which is taken out by the AMR dispatching system and sent to the corresponding AMR trolley according to certain rules to perform the handling operation; real-time messages are used In the mode, WMS sends in and out job messages in real-time, and the AMR dispatch system automatically analyzes the corresponding jobs and stores them in the database according to the message protocol, and then dispatches the corresponding AMR trolleys to perform the handling operations.

At present, the interface between WMS and AMR dispatching system is mainly through two methods: database intermediate interface table and real-time message, respectively:

- Intermediate table in the database

The information interface mode of WMS and AMR dispatching systems can adopt an intermediate database to exchange data. Relational database management systems such as Microsoft SQL Server or Oracle, establish common AMR job tables, AMR job history tables, job status tables, job type tables, job priority tables, user tables, permission tables, and log in log tables in the intermediate database, Operation log table, etc., establish a flag field in the intermediate table. The meaning of the field includes new data, read data, feedback data, read feedback data completion, delete flag, etc. through the change of the flag field value (update, insert, Delete) to complete the data interaction.

- Real-time message mode

In the WMA system implemented in the real-time data message mode, if it is necessary to interface with the AMR dispatching system, the real-time message mode is adopted. This method adopts the TCP/IP communication method, in which the WMS system is used as the server of the message, and the AMR dispatch system is used as the client of the message, and the data interface is carried out according to the communication protocol provided by the WMS.

The communication protocol includes:

- The point-to-point connection between the WMS (server) and the AMR dispatch system, including the full-duplex security message communication protocol.

- With flow control and handshake exchange mechanism for safe data transmission between systems.

- The transmitted data can be in ASCⅡ or hexadecimal format.

Through seamless and automatic docking of WMS and AMR systems that operate independently, the unity of enterprise production logistics and information flow is realized, manual operation costs are reduced, production efficiency is improved, and costs are saved for the enterprise, and the production of the enterprise is improved. The level of automation in the process.